State: OR

County:

Owner: State

Location: Rural

Spans: Three-span

Beam material: Steel

Max Span Length (ft.): 207.5

Total Bridge Length (ft.): 320.5

Construction Equipment Category: Lateral Slide

ABC Construction Equipment: Lateral slide w/pad (skids)

State ID Number: 20584

NBI Number: 20584

Coordinates

Latitude: 43.6535988 | Longitude: -100

Bridge Description

Project Summary:Project Location:

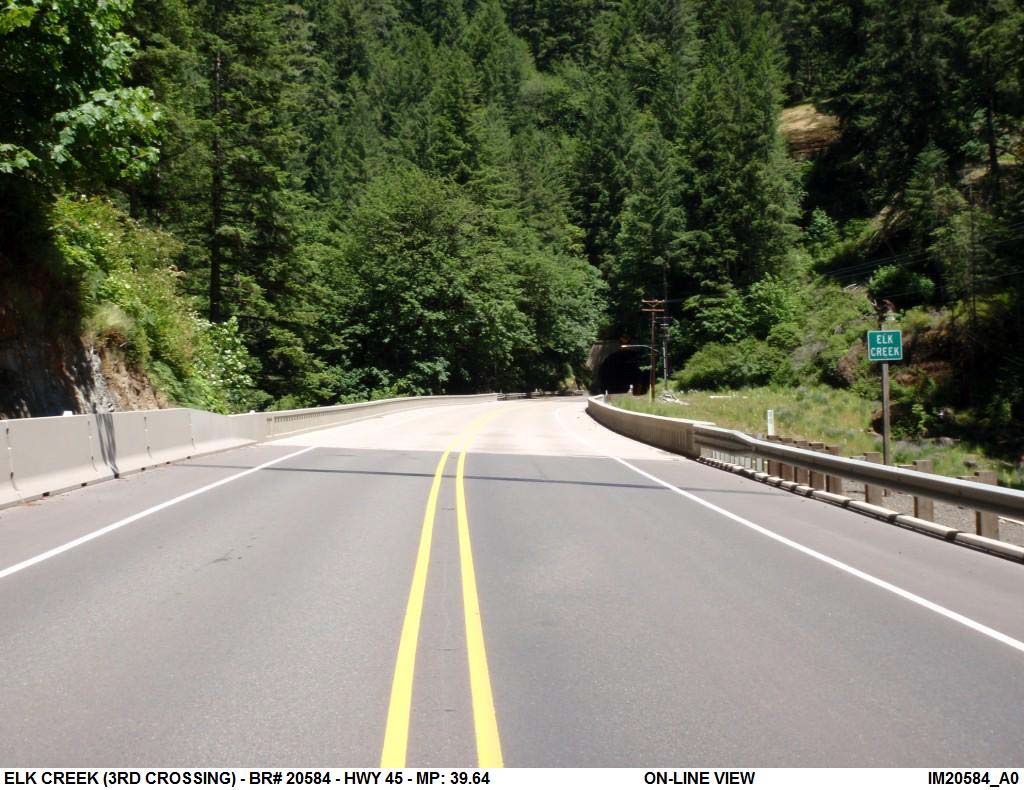

Oregon Route 38 at Milepost 39.64 over Elk Creek in Douglas County between the towns of Drain and Elkton

Impact Category:

Tier 2 (within 3 days)

Mobility Impact Time:

ABC: one weekend per bridge replacement; Conventional: two years for conventional staged construction with one lane open, for bridges #3 and #4

Primary Drivers:

reduced traffic impacts – logging trucks and commercial vehicles, and long detour route; reduced onsite construction time; improved work-zone safety; improved site constructability – close proximity of tunnel prevented construction of detour bridge; improved material quality and product durability; minimized environmental impacts – spotted owl nesting and roosting habitat

Dimensions:

320.5-ft long and 38.2-ft wide three-span (56.5 ft – 207.5 ft – 56.5 ft) steel girder bridge; 18º skew (average) and 2162.5-ft radius curve for Crossing No. 3.

Average Daily Traffic (at time of construction):

3900

Traffic Management (if constructed conventionally):

Traffic management alternative, if constructed conventionally: extended use of 50-mile detour

Existing Bridge Description:

This Oregon Highways for LIFE project consisted of replacing five structurally deficient and functionally obsolete bridges on an 11.5-mile stretch of OR 38. Crossing #3 was one of those five bridges. The existing two-lane six-span reinforced concrete deck girder bridge with steel truss was 340-ft long and 30-ft wide with pile bent substructure. It had two 12-ft-wide traffic lanes and no shoulders. Built in 1932, the bridge was deteriorated and required replacement.

Replacement or New Bridge:

The replacement bridge has two 12-ft-wide traffic lanes and two 6-ft-wide shoulders. The cross-section consists of three 7.5-ft-deep steel I-beams spaced at 14.61 ft, with a 10.75-inch-thick cast-in-place concrete deck. The deck was cast with traffic railing. The substructures were cast-in-place concrete caps and columns founded on drilled shafts.

Construction Method:

The bridge was located approximately 70 ft from the west entrance of the Elk Creek Tunnel, making construction of a detour bridge impossible. To overcome this limitation, the replacement superstructure was built adjacent to the existing bridge and laterally slid into position over a weekend.

Precast elements consisted of girders, wingwalls, sleeper slabs, and approach slabs. All precast elements were fabricated at the contractor’s yard and transported to the site for installation.With traffic maintained on the existing bridge, the construction sequence was to:

- construct a new substructure for the replacement bridge under the existing bridge while traffic was maintained (cast-in-place drilled shafts, columns, and caps)

- construct a temporary substructure for the existing superstructure on one side of the existing bridge

- construct a temporary substructure for the replacement superstructure on the other side of the existing bridge

- construct the replacement structure complete with railing

Friday evening

The existing bridge was closed to traffic at 8 pm, with traffic detoured for the two-day closure. Preliminary work included removing the asphalt overlay, bridge railings, and approach slabs.

Saturday – Sunday

The old superstructure was lifted and slid laterally onto temporary supports using hydraulic jacks mounted on sliding rails. Similarly, the replacement bridge was slid laterally onto the original alignment. The moves took about four hours to complete. Backfill was placed. Precast wingwalls, sleeper slabs, and approach slabs were installed. Finish work required prior to opening the bridge was completed.

Monday morning

The bridge was opened to traffic at 5:00 am.

Subsequently the old superstructure was demolished and the temporary supports were dismantled.

The contract included incentive / disincentive clauses of $20,000 for each day the bridge was opened in less than 30 days, with a maximum of $600,000 for crossings 3 and 4. The contractor was awarded the maximum incentive.

Stakeholder Feedback:

ABC over a weekend closure was the way to go for a corridor with a shortest detour route of 50 miles. The public outreach was outstanding as it involved the Elkton community to provide full support for the weekend closure of the facility for rapid construction and project delivery.

High Performance Material:

High-performance concrete (HPC) bridge decks

Project Planning

Decision Making Tools: State processSite Procurement: early environmental clearance & permitting

Project Delivery: design-build

Contracting: full lane closure; incentive / disincentive clause

Geotechnical Solutions

Foundations & Walls: CIP substructure under trafficRapid Embankment:

Structural Solutions

Prefabricated Bridge Elements: Precast wingwallPrefabricated Bridge Systems: FDcBs (full-width concrete-decked steel beam unit)

Miscellaneous Prefabricated: CIP reinforced concrete closure joint; precast approach slab; other miscellaneous prefabricated element – precast sleeper slab

Costs & Funding

Costs:The cost for all five bridges on this design-build project was $50.8 million, of which this bridge cost $12.3 million. ODOT realized a total cost savings of $2.4 million (5% of total project cost) over conventional construction practices due to reduced construction duration, mobilization costs, reduced delay cost, and the use of innovative bridge removal and replacement techniques.ABC techniques saved an estimated $500,000 in delay-related user costs.

Funding Source:

Federal and State

Incentive Program:

HfL (Highways for Life): $1,000,000

Additional Information

Downloadable Resources

Contract Plans: View Drawings-ECC3-and-4-Bridges.pdf

Bid Tabs:

View Change-Management-201110321.pdf

Other Related Information:

Summary Sheet:

130204-ABC_New_Elk-Creek-3

Other Related URLs:

Go to:

http://www.gostructural.com/magazine-article-gostructural.com-4-2012-turning_challenges_into_community_connections-8814.html

Go to:

http://www.fhwa.dot.gov/hfl/summary/or/

Go to:

http://www.fhwa.dot.gov/hfl/innovator/issue08.cfm

Go to:

http://www.oregon.gov/ODOT/HWY/BRIDGE/

Oregon Department of Transportation

Contacts

Bruce V. Johnson, P.E.

State Bridge Engineer

Oregon Department of Transportation

bruce.v.johnson@odot.state.or.us

503-986-3344