State: NY

County:

Owner: State

Location: Rural

Spans: One-span

Beam material: Steel

Max Span Length (ft.): 131.2

Total Bridge Length (ft.): 131.2

Construction Equipment Category: Conventional

ABC Construction Equipment: Conventional

State ID Number: 1017580

NBI Number: 1017580

Coordinates

Latitude: 42.4700012 | Longitude: -75.1083298

Bridge Description

Project Summary:New York State's second use of ultra-high performance concrete (UHPC) deck closure joints

Project Location:

NYS Route 23 in Otsego County near the village of Oneonta

Impact Category:

Tier 5 (within 3 months)

Mobility Impact Time:

Primary Drivers:

reduced traffic impacts, improved material quality and product durability, improved site constructability

Dimensions:

131.2-ft long and 42.7-ft wide single-span steel plate girder bridge

Average Daily Traffic (at time of construction):

6903

Traffic Management (if constructed conventionally):

onsite detour

Existing Bridge Description:

The existing two-lane bridge, consisting of steel through girders on concrete deck, was deteriorated and required replacement.

Replacement or New Bridge:

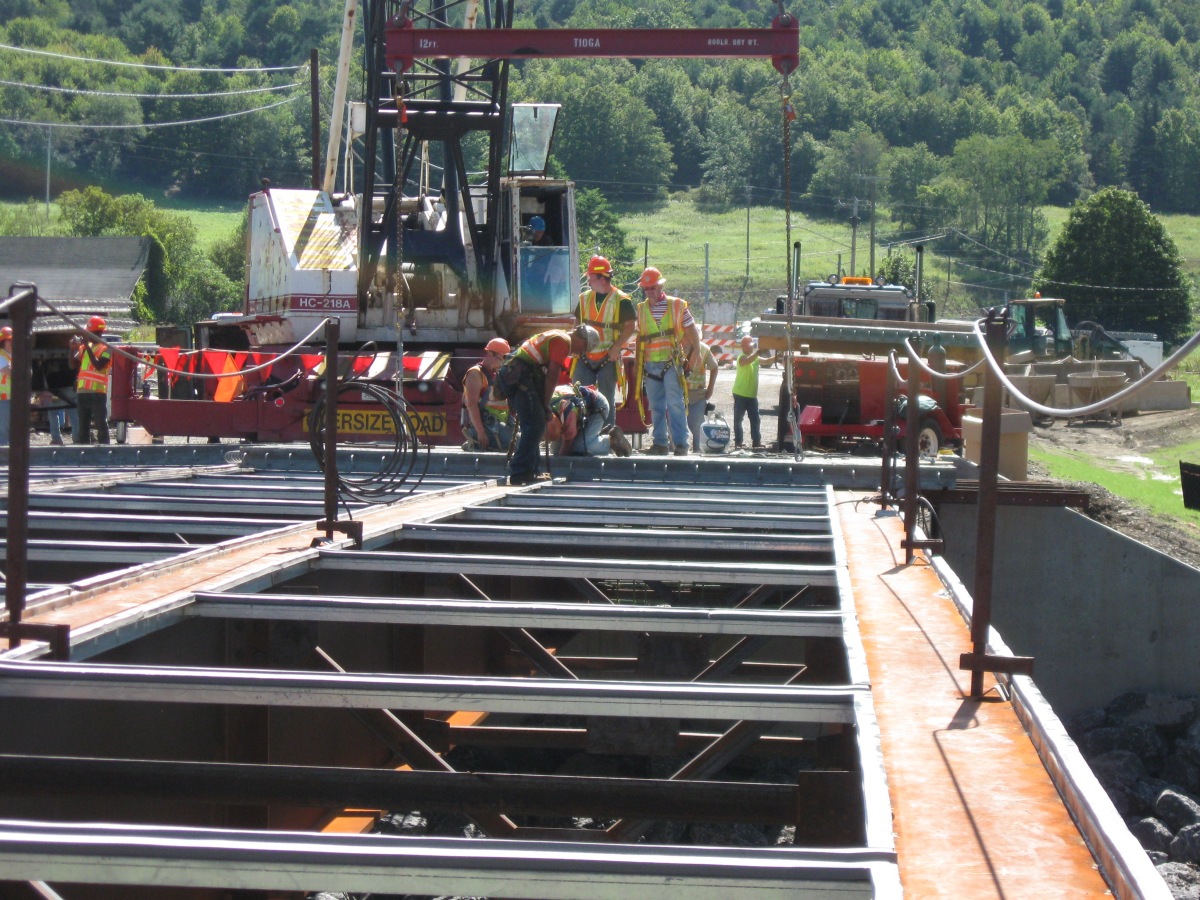

The two-lane steel stringer integral abutment replacement bridge is New York State’s second use of ultra-high-performance concrete (UHPC) deck closure joints. The bridge consists of five 56-inch-deep steel plate girders spaced at 9.18 ft. The 8-inch-thick precast deck panels were installed on the beams, and UHPC was used to connect the panels in a six-inch-wide closure joint between panels.

Construction Method:

The 5,436 sq ft of precast deck panels were fabricated with projecting galvanized bars that were spliced with the bars projecting from adjacent panels. After the beams and panels were erected, joint formwork was placed and the joints were filled with UHPC. The closure joints were then covered and cured. After curing, a 2-inch-thick concrete overlay was placed to provide a smooth riding surface.

Stakeholder Feedback:

The use of UHPC eliminated the need to post-tension the deck panels, which decreased the duration of construction. Also, NYSDOT anticipates that the cost will be reduced for future projects using UHPC joint fill as contractors become more familiar with the UHPC material and processes.

High Performance Material:

UHPC, galvanized bars

Project Planning

Decision Making Tools:Site Procurement:

Project Delivery: Design-bid-build

Contracting:

Geotechnical Solutions

Foundations & Walls:Rapid Embankment:

Structural Solutions

Prefabricated Bridge Elements: Full-depth precast deck panel w/o PT (with UHPC closure joints)Prefabricated Bridge Systems:

Miscellaneous Prefabricated: CIP reinforced closure joints, UHPC closure joints, standard concrete overlay

Costs & Funding

Costs:The engineer’s estimate for the project was $1.78m. The low bid was $1.46m.

Funding Source:

Federal and State

Incentive Program:

Additional Information

Downloadable Resources

Contract Plans:Specifications:

Bid Tabs:

Construction Schedule:

Other Related Information:

New York State Department of Transportation

Contacts

Richard Marchione,

P.E.

Director, Office of Structures

New York State Department of Transportation

Richard.Marchione@dot.ny.gov

518-457-6827

Submitter:

Mary Lou Ralls

P.E.

Principal

Ralls Newman, LLC

ralls-newman@sbcglobal.net

512-422-9080

Contractor:

Tioga Construction Company, Inc.