State: UT

County:

Owner: State

Location: Urban

Spans: Two-span

Beam material: Steel

Max Span Length (ft.): 177

Total Bridge Length (ft.): 354

Construction Equipment Category: SPMTs

ABC Construction Equipment: SPMT(s)

State ID Number: MP-l15-6(178)245

NBI Number: 0C 989

Coordinates

Latitude: 40.355545 | Longitude: -100

Bridge Description

Project Summary:Project Location:

On Sam White Lane over I-15 in the city of American Fork in Utah County, 30 miles south of Salt Lake City

Impact Category:

Tier 1 (within 1 day)

Mobility Impact Time:

ABC: overnight closure of I-15 (8 hrs); Conventional: Six additional full nighttime I-15 closures

Primary Drivers:

Reduced onsite construction time; reduced traffic impacts; improved work-zone safety; improved site constructability; improved material quality and product durability

Dimensions:

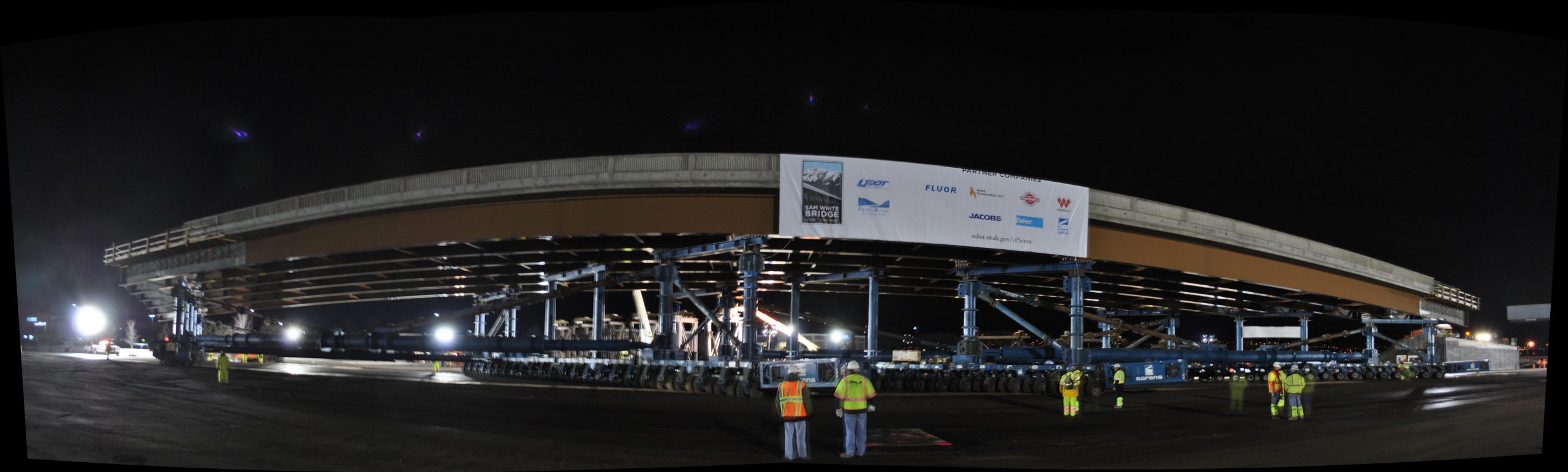

354-ft long and 76.8-ft wide two-span continuous steel plate-girder bridge (177 ft – 177 ft) roll-in; 48º skew; 1,910-ton self-weight

Average Daily Traffic (at time of construction):

65800

Traffic Management (if constructed conventionally):

Traffic management alternative, if constructed conventionally: would have impacted I-15 traffic (extended use of multiple lane closures)

Existing Bridge Description:

The existing four-span bridge was 325 ft long and 34 ft wide with a minimum vertical clearance of 14 ft-7 inch. It was demolished in 2008 after being severely damaged by a collision.

Replacement or New Bridge:

The Sam White Bridge is the longest bridge in the US to be moved into its final location using self-propelled modular transporters (SPMTs). It crosses I-15 at a high skew and on a sharp vertical curve. The bridge has two 12-ft-wide traffic lanes in each direction, a 14-ft-wide turn lane, and a 12-ft-wide shoulder and 6-ft-wide sidewalk on each side. The 7-ft-deep cross-section consists of six steel plate girders at 13.5-ft spacing with 4.67-ft overhangs and a 10-inch-thick cast-in-place lightweight concrete deck. It has a 17.25-ft vertical clearance above I-15.

Construction Method:

From August 2010 to March 2011, the bridge was built on the east side of I-15 approximately 500 ft from the bridge location. The abutments and interior support were constructed conventionally with concrete-filled pipe pile foundations. The interior support consists of six individual 4-ft-square cast-in-place concrete columns spaced at 20 ft. Each girder was set directly on a column. Each girder was connected to the column with an over-sized interlocking sole plate on a steel-reinforced elastomeric bearing pad; the connection accommodated setting tolerances during the bridge move as well as subsequent loading due to girder rotation and movements due to temperature and seismic effects. Saturday EveningOn March 26, I-15 was closed at 11 pm. At the bridge temporary location the two-span unit was lifted off the temporary supports on four lines of self-propelled modular transporters (SPMTs) (two lines per span), and moved 500 ft across eight lanes of I-15 to the final bridge location.Sunday MorningThe bridge was set in place at approximately 4 am. I-15 was re-opened at 7 am, three hours ahead of schedule. The abutments were made integral after the move, and a thin-bonded polymer overlay was placed.

Stakeholder Feedback:

High Performance Material:

Lightweight concrete deck, 70 ksi high performance steel (HPS) in girder flanges over the interior support

Project Planning

Decision Making Tools: State processSite Procurement:

Project Delivery: Design-build

Contracting: Full lane closure

Geotechnical Solutions

Foundations & Walls:Rapid Embankment:

Structural Solutions

Prefabricated Bridge Elements:Prefabricated Bridge Systems: FDcBs (full-width concrete-decked steel beam unit)

Miscellaneous Prefabricated: CIP reinforced concrete closure joints; Thin-bonded epoxy overlay; LWC deck

Costs & Funding

Costs:This bridge is part of the $1.7 billion Utah County Corridor Expansion (CORE) design-build project. The construction cost of the bridge was $5.09 million. The estimated cost of accelerated techniques was approximately $1.75 million.

Funding Source:

State Only

Incentive Program:

Additional Information

Downloadable Resources

Contract Plans:Specifications:

View Sam-White_special-provisions.pdf

Construction Schedule:

Other Related Information:

Summary Sheet:

120131-ABC_New2_UT_2011_Sam-White

Other Related URLs:

Go to:

http://www.udot.utah.gov

Go to:

http://www.youtube.com/watch?v=IqyZ1HT0yMA

Go to:

http://www.youtube.com/watch?v=6yAlAGnKxSY

Go to:

http://www.i15core.utah.gov/bridge/

Utah Department of Transportation

Contacts

Carmen Swanwick, P.E.

Chief Structural Engineer

Utah Department of Transportation

cswanwick@utah.gov

801-965-4981