State: SC

County:

Owner: State

Location: Urban

Spans: > Three-span

Beam material: Steel

Max Span Length (ft.): 247

Total Bridge Length (ft.): 1154

Construction Equipment Category: Lateral Slide

ABC Construction Equipment: Lateral slide w/pad (skids); Float in

State ID Number: 1303

NBI Number: 1.04E+12

Coordinates

Latitude: 32.7727776 | Longitude: -79.8419418

Bridge Description

Project Summary:Project Location:

SC 703 over the Intracoastal Waterway in Charleston

Impact Category:

Tier 3 (within 2 weeks)

Mobility Impact Time:

ABC: 12-day closure ; Conventional: 8-month total bridge closure

Primary Drivers:

Reduced traffic impacts – to both highway and marine traffic; Minimized environmental impacts – the bridge was rehabilitated on the existing alignment with no new right-of-way and only a slight shift in the roadway centerline

• No temporary or permanent fill was placed in the critical area wetlands during construction

• An access trestle was used during construction to minimize construction impacts to critical areas; this trestle allowed daily tidal inundation in the construction zone

• Construction of the new swing span was completed offsite to reduce the impacts to wetland areas

• Marsh areas impacted by the access trestle were returned to original contours, re-vegetated, and monitored after construction

• Reduced onsite construction time:

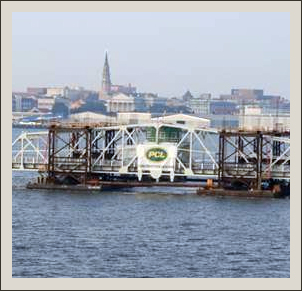

• Swing span built offsite and barged to site complete with deck

• Two units of three spans, on each side of swing span, were built on temporary false work adjacent to existing bridge and horizontally pulled into position

• Improved work-zone safety – for construction workers and traveling public; excellent safety record by contractor

• Improved material quality and product durability – the swing span and approach spans were constructed away from traffic and off the project’s critical path, allowing contractor to concentrate on workmanship

• Reduced life-cycle costs – the structural efficiency of the lightweight deck system resulted in savings in truss design and reduced load on the existing center pier

Dimensions:

1,154-ft-long and 36.5-ft-wide 13-span bridge (two 70 ft – 86 ft – 70 ft continuous approach units each end and 247-ft-long bolted steel through-truss swing span)

Average Daily Traffic (at time of construction):

14100

Traffic Management (if constructed conventionally):

Traffic management alternative, if constructed conventionally: 11.5-mile detour

Existing Bridge Description:

Named after former SCDOT Chief Highway Commissioner / Executive Director (1926 to 1940), the historic two-lane bridge was built in 1945 to connect the towns of Sullivan’s Island and Mount Pleasant over the Atlantic Intracoastal Waterway. The swing-span truss and approach spans were deteriorated and required replacement.

Replacement or New Bridge:

The public requested that the new superstructure be similar in aesthetic appearance to the existing bridge and maintain the navigational channel clearances. Accordingly the new swing span is a 640-ton center-pivot modified Pratt through-truss with top and bottom chords at the same elevation as the existing truss, and with new electrical and mechanical systems. It matches the appearance of the original swing span except that the roadway was widened to accommodate two 14-ft-wide lanes instead of the existing 12-ft lanes, and one 5.5-ft-wide sidewalk on the harbor side instead of the two existing 2.5-ft-wide sidewalks. The 7-inch-thick Exodermic™ replacement deck consists of a 2.875-inch-thick steel grid with 4.125-inch-thick precast lightweight reinforced concrete composite topping. The cross-section of the approach spans consists of two 5.75-ft-deep steel plate girders spaced at 23 ft (with floor beams), with an 8-inch-thick lightweight concrete deck.

Construction Method:

The new swing span was constructed offsite at the former Navy Base in North Charleston approximately two miles from the bridge site. The Exodermic™ deck panels were shop cambered to the specified roadway cross-slope crown. Approximately 7,000 sq ft of panels were placed on the truss prior to casting the concrete. The sidewalk is composed of aluminum deck panels, and the steel railing is similar in appearance to the old swing span. The six approach spans on each end of the swing span were built on temporary false work adjacent to the existing bridge on the south side while traffic was maintained. The approach spans were conventionally constructed with lightweight reinforced concrete decks on steel girders. The existing substructure was rehabilitated. Single-lane closures from 9 pm to 5 am were required prior to the 10-day bridge closure. 10-day Closure (this period was extended to 12 days):The Intracoastal Waterway was closed to marine traffic from February 7, 2010 to February 18, 2010. Its closure began just before the swing span was lifted from its temporary supports in North Charleston on barges and traveled under the Cooper River Bridge through the harbor to the bridge site. The bridge was closed, and the existing approach spans were transversely shifted onto temporary supports adjacent to the existing bridge piers. The six new approach spans on one end were simultaneously pulled 30 ft transversely along horizontal tracks onto the existing piers that had been retrofitted with seismic isolation bearings. The six new spans on the other end were then also pulled into position as a unit. Each approach was moved in approximately 24 hours using post-tensioning jacks with jack stroke limited to three inches each pull.The barges then brought the new swing span from its nearby holding location and lifted the existing swing span off its pivot pier. The barges then backed up, lowered the old span, rotated 180 degrees, moved back in, and lowered the new span into position. The old swing span was then barged back to the pier in North Charleston for demolition. The existing approach spans were demolished on their temporary supports adjacent to the new bridge.After the new bridge was on the original alignment, several days of additional work were required prior to opening the bridge, for example, grinding the deck for improved rideability, completing electrical and utility connections, and testing mechanical and electrical equipment on the swing span. No deck overlay was applied.The contract included an incentive of $2,500 per hour for completing the work under the total bridge closure time of less than 168 hours (seven days). A maximum payment of $120,000 (48 hours) was specified. However, damage to the bridge’s pivot pier was found during construction, and an additional 66 hours was added to the closure time for its repair, for a maximum allowable closure time of 10 days.The contract also included liquidated damages of $2,900 per day for each calendar day by which the period from the Notice to Proceed to Substantial Completion of the entire project exceeded the specified contract time. In addition, the contract specified liquidated damages of $2,500 per hour of total bridge closure that exceeded the allowed total closure time. The contractor was also required to maintain two lanes of traffic, one in each direction, at all times except during scheduled closures. If violated, the contractor would pay a penalty of $2,500 for each ¼-hour interval (or any portion thereof). If the violation continued beyond one hour, the penalty would be increased to $5,000 for each ¼-hour interval (or any portion thereof).The Intracoastal Waterway and the bridge were closed a total of 12 days. During the closure, the contractor maintained a 24-hr work schedule. A total bridge closure of eight months minimum would have been required for conventional construction. The total project was completed in 18 months compared to 24 months that would have been required for conventional construction.

Stakeholder Feedback:

See “Other Related Information” for lessons learned.

High Performance Material:

Lightweight concrete deck

Project Planning

Decision Making Tools:Site Procurement:

Project Delivery: Design-build

Contracting: Full lane closure; Incentive / disincentive clauses

Geotechnical Solutions

Foundations & Walls: Reused substructure/foundation unitRapid Embankment:

Structural Solutions

Prefabricated Bridge Elements: Exodermic deckPrefabricated Bridge Systems: Truss span w/deck; FDcBs (full-width concrete-decked steel beam unit)

Miscellaneous Prefabricated: LWC deck

Costs & Funding

Costs:The project cost of $32.5 million was 100% federally funded. Conventional construction would have cost approximately $4.8 million less. The reduced closure time saved an estimated $6.5 million in vehicle operating costs and user delay costs that would have been required for extended use of the detour, resulting in a net savings of $1.7 million.

Funding Source:

Federal Only

Incentive Program:

HfL (Highways for LIFE): $1,000,000

Additional Information

Downloadable Resources

Contract Plans: View SC-BenSawyer-DeckDetail.pdf

View SC_703_Ben_Sawyer__RFP.pdf

View Addendum_No__1_Question_Response.pdf

View Attachment_A-Agreement_Exhibit1-9-1.pdf

Construction Schedule:

Other Related Information:

SC-BenSawyer-LessonsLearned

Summary Sheet:

130227-ABC_New_SC_2010_Hwy-703-Ben-Sawyer

Other Related URLs:

Go to:

http://www.fhwa.dot.gov/hfl/summary/pdfs/sc_703.pdf

South Carolina Department of Transportation

Contacts

Barry W. Bowers, P.E.

Structural Design Support Engineer

South Carolina Department of Transportation

bowersbw@scdot.org

803-737-4814