State: VT

County:

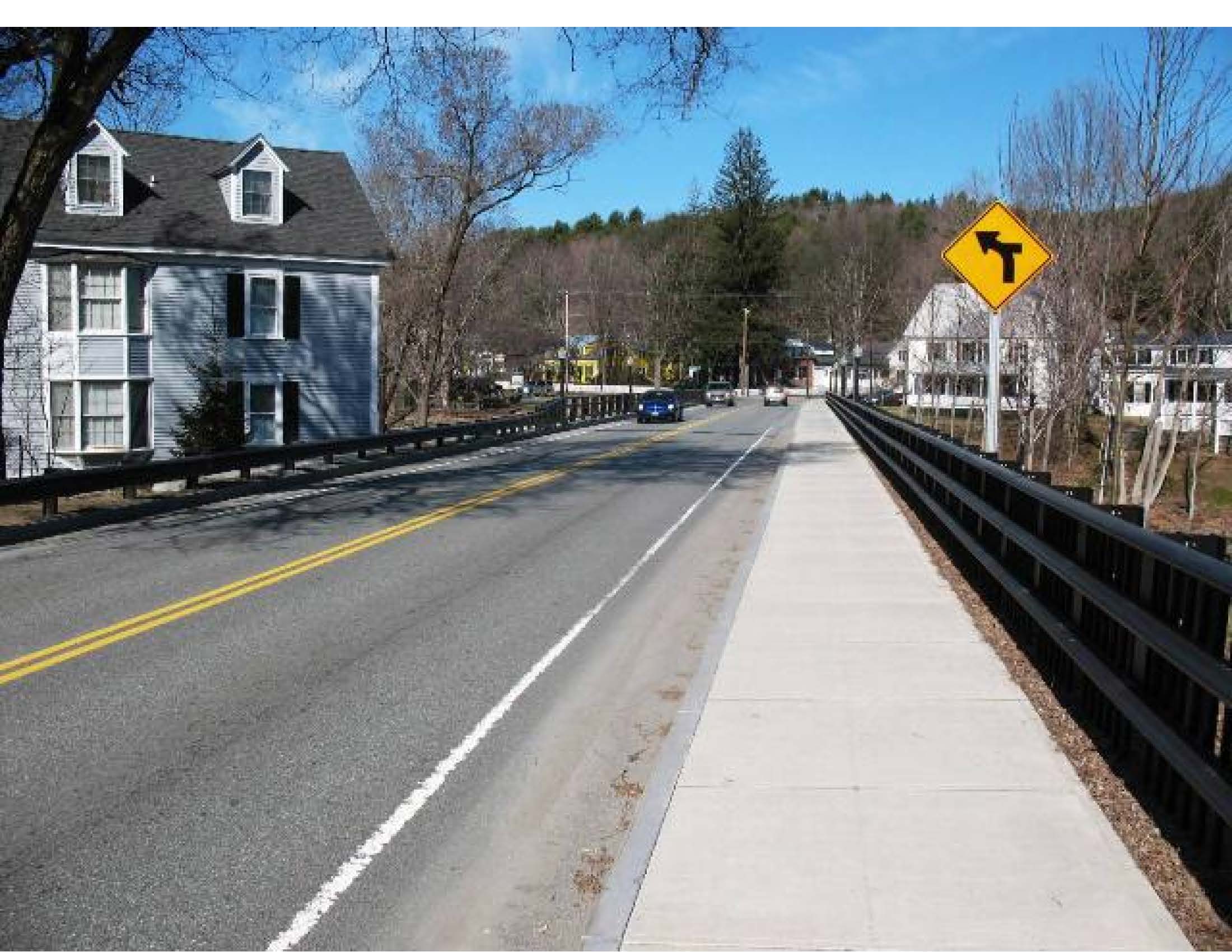

Owner: Town of Woodstock

Location: Urban

Spans: Three-span

Beam material: Concrete

Max Span Length (ft.): 84

Total Bridge Length (ft.): 202.5

Construction Equipment Category: Conventional

ABC Construction Equipment: Conventional

State ID Number: BHF 020-2(32)

NBI Number: 2E+14

Coordinates

Latitude: 43.6222229 | Longitude: -72.5255585

Bridge Description

Project Summary:Project Location:

Bridge #50 on US Route 4 (principal arterial) over the Ottauquechee River in the town of Woodstock in Windsor County

Impact Category:

Tier 4 (within 1 month)

Mobility Impact Time:

ABC: 27-day closure; Conventional: 6-month closure; 2 construction seasons

Primary Drivers:

reduced traffic impacts, reduced onsite construction time, improved work-zone safety

Dimensions:

202.5-ft long and 37.5-ft wide 3-span pre-tensioned box beam bridge (58 ft – 84 ft – 58 ft); 30º skew

Average Daily Traffic (at time of construction):

14200

Traffic Management (if constructed conventionally):

Traffic management alternative, if constructed conventionally: extended use of 24-mile detour

Existing Bridge Description:

The existing 179.3-ft-long steel beam bridge with concrete deck was built in 1938 and rehabilitated in 1954. The superstructure was deteriorated and required replacement.

Replacement or New Bridge:

The replacement bridge has two 11-ft-wide traffic lanes, two 3-ft-wide shoulders, and a 6-ft-wide sidewalk. The cross-section consists of eight 4-ft-wide boxes and one 3-ft-wide box. The 27-inch-deep voided boxes are adjacent except for the 4-ft-wide box under the sidewalk, which has a 1.7-ft clear spacing for future utilities. Box sections were fabricated with lightweight concrete to minimize loading on the existing substructures. Mid-depth transverse post-tensioning ducts are spaced at 15-18 ft. The boxes have a minimum 4-inch-thick concrete topping, covered by a waterproofing membrane and 2.50-inch-thick asphalt overlay.

Construction Method:

Designers added a construction joint to the pier encasements just below the bearing seats so that all concrete below the joint could be completed under traffic and concrete above the joint could be placed after the superstructure was removed. Prior to closing the bridge the contractor built cofferdams at the interior piers. Crews made concrete repairs to abutments and piers and constructed the concrete encasements for the piers while the existing bridge remained in service. The contractor closed the bridge and demolished the existing superstructure. Deteriorated portions of the existing abutments, wingwalls, and piers were removed as shown on the plans and directed by the resident engineer, without allowing debris to fall into the river. The resident engineer established actual removal and repair limits on the abutments and piers after a joint inspection by the contractor and the engineer. Repairs were made to the existing substructure, and cast-in-place caps were constructed over remaining abutments and piers. The contractor erected the box beams on elastomeric bearing pads. A 1.5-inch-diameter anchor bolt hole was drilled vertically through the cap into the existing substructure using the 2.5-inch-diameter sleeves in the ends of the beams. A 3.5-ft-long 1.25-inch-diameter anchor bolt was inserted into the hole and the hole was filled with grout. Transverse post-tensioning strands were threaded through the boxes and lightly tensioned to remove sags and to seat the chucks. The shear keys were grouted. After the grout reached 1,500 psi compressive strength, the transverse post-tensioning strands were tensioned to 30 kips. The concrete topping and diaphragms at the ends of the beams were cast. New retaining walls were constructed using a proprietary modular block wall system that was value engineered into the project. Related channel work completed. The bridge was opened to two-way traffic. Membrane waterproofing and asphalt overlay were placed and traffic railing cast with temporary lane closures.The contract included a lump sum incentive of $50,000 if the bridge was opened to two-way traffic within 27 days. The contract also included an incentive of $200 per hour the bridge was opened to two-way traffic before 11:59 pm on the 27th day. The maximum incentive was set at $80,000. For each hour after 11:59 pm on the 27th day that the bridge remained closed, the contract also included a disincentive of $300 per hour for the first 12 hours, $400 per hour for the next 12 hours, and $600 per hour thereafter with no maximum amount for disincentives. The bridge was opened to two-way traffic nine hours before the incentive/disincentive deadline.

Stakeholder Feedback:

(1) The Public Relations Officer included as a contract item and hired by the contractor during construction is a very important role and is key to how well these projects are tolerated by the public. (2) The contractor worked 24/7 for 27 straight days to complete this project. This concentrated effort over this duration can create stress and fatigue for field personnel. (3) Sub-consultants can control the pace of work and may not be aware of the incentive / disincentive on the prime contractor. (4) Designers must be available to answers questions during the closure and empowered to make major decisions. (5) Advertise much earlier than usual to give the contractor time to get the work scheduled and also to provide a time to submit changes for consideration.

High Performance Material:

3,500 – 4,000 psi high-performance concrete (HPC) – all concrete on job; Lightweight HPC in pretensioned box beams, w/ 0.6-inch diameter strands

Project Planning

Decision Making Tools: Other decision-making tool: Stakeholder Meetings held to present alternativesSite Procurement: Right-of-Way acquisition

Project Delivery: Design-bid-build

Contracting: Full lane closure; Incentive / disincentive clause; Lump sum bonus; Value Engineering

Geotechnical Solutions

Foundations & Walls: CIP substructure under trafficRapid Embankment:

Structural Solutions

Prefabricated Bridge Elements: Adjacent box beams, Modular block wallsPrefabricated Bridge Systems:

Miscellaneous Prefabricated: CIP reinforced concrete closure joint; Grouted key closure joint; Asphalt overlay w/membrane; LWC beams

Costs & Funding

Costs:The engineer’s estimate for the project was $3.06 million. The low bid was $3.51 million. There were three bidders. The cost per square foot of bridge was $462. The cost per sq ft for conventional construction in this region in 2007 was not calculated; valid comparison to conventional construction would have been difficult since extensive substructure repairs were made.Federal, state, and local funding (80%-15%-5%) was used to finance this project.

Funding Source:

Other

Incentive Program:

IBRC (Innovative Bridge Research and Construction Program): $200,000

Additional Information

Downloadable Resources

Contract Plans:Specifications:

View 93j028_Draft-Specials-10-12-2006.pdf

View 93j028_Results-of-Bids.pdf

View Woodstock-061011-Bid-Estimate.pdf

View ConstructionSchedule-Engineers.pdf

Other Related Information:

20060829-Rutland-Herald-29Aug06

20061006-Rutland-Herald-06Oct06

20061020-Rutland-Herald-20Oct06

20061129-Rutland-Herald-29Nov06

20070407-Rutland-Herald-26april07

20070603-Rutland-Herald-3jun07

20070613-Rutland-Herald-13Jun07

20070629-Rutland-Herald-29jun07

20061021-TimesArgus-21Oct06

20070622-VAlleyNews-22June07

Summary Sheet:

120427-ABC_New_VT_2007_Rte-4-over-Ottauquechee-River

Other Related URLs:

Vermont Agency of Transportation

Contacts

Christopher P. Williams, P.E.

Senior Project Manager, Structures Section

Vermont Agency of Transportation

chris.williams@state.vt.us

802-828-0051