State: MO

County:

Owner: State

Location: Rural

Spans: > Three-span

Beam material: Steel

Max Span Length (ft.): 90

Total Bridge Length (ft.): 1698

Construction Equipment Category: Conventional

ABC Construction Equipment: Conventional

State ID Number: A0894

NBI Number: 649

Coordinates

Latitude: 37.8650017 | Longitude: -93.2816696

Bridge Description

Project Summary:Project Location:

On Route 64 over the Lindley Creek arm of the Pomme De Terre Lake in southern Hickory County near the town of Nemo in the Missouri Ozarks

Impact Category:

Tier 6 (longer but reduced by months/years)

Mobility Impact Time:

ABC: 3 month overnight closures; 1 month of one-lane closures; Conventional: 2 yrs of one-lane closures

Primary Drivers:

reduced traffic impacts, reduced onsite construction time, improved site constructability

Dimensions:

1,698-ft long and 27.5-ft wide 19-span five unit (275 ft - 360 ft - 360 ft - 360 ft - 329 ft) composite steel I-girder bridge

Average Daily Traffic (at time of construction):

3290

Traffic Management (if constructed conventionally):

Traffic management alternative, if constructed conventionally: two years of one-lane closures; 28-mile detour

Existing Bridge Description:

The existing two-lane 22-ft-wide bridge had two 11-ft-wide traffic lanes. The cross-section consists of four 3-ft-deep steel I-girders at 6.67-ft spacing, with a 7-inch-thick composite reinforced concrete deck. Built in 1960 by the US Army Corps of Engineers, the bridge had a deteriorated deck that was too narrow and required replacement.

Replacement or New Bridge:

Construction Method:

The contractor cast the 162 precast deck panels on a 29-ft by 360-ft casting bed adjacent to the bridge site. The 10-ft-long segments of 27.5-ft-wide, 9-inch-thick panels with epoxy-coated reinforcement were match cast for the entire length of each of the five continuous sections between expansion joints. The project also included replacing expansion joints, re-painting the steel girders, and replacing the abutment backwalls.

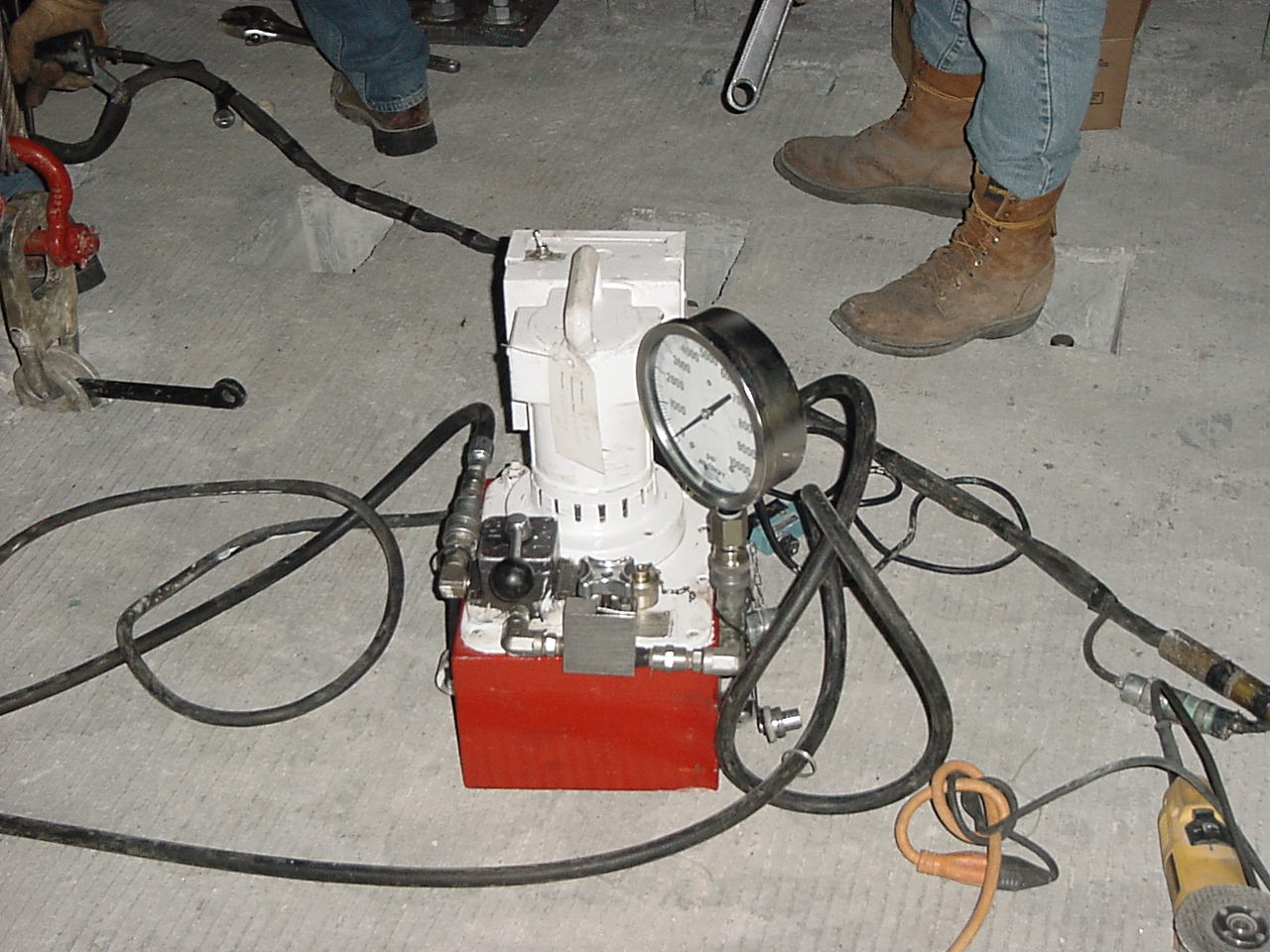

During nighttime closures, the contractor removed an old deck section, removed the old shear studs and painted the tops of the girders, coated the match-cast panel edge with epoxy, set the panel, and repeated the process. After panels were set, shear studs were welded to the girders in the blockout locations. Adjacent panels were post-tensioned together with eight 1-inch-diameter epoxy-coated bars, and haunches and blockouts were filled with fast-setting grout cast through the blockout openings. The contractor set from 30 ft to 80 ft of panels each night. A short transition length was left between the panels and existing deck using steel grid as the temporary riding surface.

Cast-in-place closure joints connected the panels and the new expansion joints. The bridge was opened to traffic when the grout reached 2,500 psi. The post-tensioning ducts were grouted at a later date.

The traffic barrier was slip-formed after all panels were erected during one-lane closures after Labor Day. Similarly, the 1.5-inch-thick micro-silica overlay was placed half-width at night during one-lane closures after Labor Day.

The contract required that the bridge be closed only on Sunday through Thursday from 7 pm to 7 am between the Memorial Day weekend and the Labor Day weekend. The contract also included a disincentive of $143 for every five minutes that the lanes were opened late. The contract also required that the bridge be opened by the November 30, 2004 completion date, to avoid liquidated damages of $2,300 per day.

Stakeholder Feedback:

MoDOT anticipates the new panels, the new expansion joints, and the rehabilitation and painting of the steel girders will add another 50 years to the bridge’s service life. In addition, MODOT believes that the significant reduction in construction time was greatly appreciated by the public due to the 28 mile detour.

MoDOT was pleased with the outcome of this project; However, because of funding restraints and the higher cost of this type of deck replacement, we have not been able to use this application in other locations.

High Performance Material:

7000 psi expanding grout, quick drying organic zinc primer

Project Planning

Decision Making Tools: State processSite Procurement: Right–of-way acquisition (for dock easement only)

Project Delivery: Design-bid-build

Contracting: Full lane closure, Incentive / disincentive clause

Geotechnical Solutions

Foundations & Walls:Rapid Embankment:

Structural Solutions

Prefabricated Bridge Elements: Full-depth precast deck panel w/PTPrefabricated Bridge Systems:

Miscellaneous Prefabricated: CIP reinforced concrete closure joint, Grouted blockout w/shear connectors, PT ducts/bonded, Match cast closure joint, Micro-silica concrete overlay

Costs & Funding

Costs:The engineer’s estimate for the project was $ 5.343 million. The low bid was $5.51 million ($178,000 = 3.14% higher than engineer’s estimate). There were 3 bidders. The cost per square foot of bridge was $98.25 compared to $60 for conventional construction in this region in 2004.

ABC techniques saved an estimated $230 thousand in delay-related user costs. The net additional cost on the project totaled approximately $1.77 million or 63 percent over conventional construction.

Funding Source:

Federal Only

Incentive Program:

IBRC (Innovative Bridge Research and Construction Program): $160,000

Additional Information

Downloadable Resources

Contract Plans: View Nemo-Contract-Plans_A0894-Rehabs.pdf

View Nemo-Special-Provisions.pdf

View Nemo-bid-tabs-March-19-2004.pdf

View Nemo-Contractors-Work-Schedule.pdf

Other Related Information:

March-2005-MODOT-Research-Brief

August-2005-MODOT-Research-Report-R104.027

Other Related URLs:

Missouri Department of Transportation

Contacts

Dennis Heckman,

P.E.

State Bridge Engineer

Missouri Department of Transportation

dennis.heckman@modot.mo.gov

573-751-4676

Submitter:

Mary Lou Ralls, P.E.

Principal Ralls Newman, LLC

ralls-newman@sbcglobal.net

512-422-9080

Designer Company Name:

HNTB