State: NH

County:

Owner: Town of Epping, NH

Location: Rural

Spans: One-span

Beam material: Concrete

Max Span Length (ft.): 115

Total Bridge Length (ft.): 115

Construction Equipment Category: Conventional

ABC Construction Equipment: Conventional

State ID Number: Epping 112/055

NBI Number: 7.8E+12

Coordinates

Latitude: 43.0380554 | Longitude: -71.0708313

Bridge Description

Project Summary:Project Location:

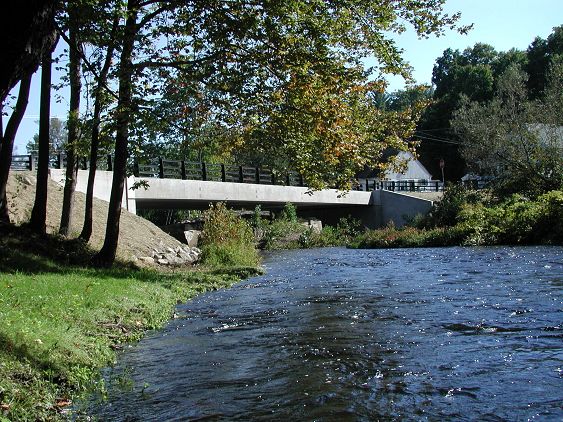

on Mill Street over the Lamprey River in the town of Epping in Rockingham County

Impact Category:

Tier 3 (within 2 weeks)

Mobility Impact Time:

ABC: 8 days to erect bridge; 2-month closure; Conventional: 5-month closure

Primary Drivers:

Reduced traffic impacts, reduced onsite construction time – rapid assembly time may preclude the need for a detour

Dimensions:

115-ft long and 28-ft wide single-span adjacent box beam bridge

Average Daily Traffic (at time of construction):

500

Traffic Management (if constructed conventionally):

Traffic management alternative, if constructed conventionally: extended use of half-mile detour

Existing Bridge Description:

The existing 28-ft wide two-lane bridge consisted of two 30-ft long spans separated by a 60-ft long center pier causeway. Built in 1935, the spans were deteriorated and required replacement.

Replacement or New Bridge:

The two-lane replacement bridge consists of a pretensioned concrete adjacent box beam superstructure on full-height cantilevered precast concrete abutments founded on precast concrete spread footings. Thirty-two precast concrete segments were used to construct the bridge. The 32.4-ft wide 5,000 psi precast reinforced self-consolidating high-performance concrete (HPC) abutments consist of 10 spread footing segments and 11 abutment wall and wingwall segments. The superstructure consists of seven 4-ft-wide 3-ft-deep adjacent box beams made of 8,000 psi pretensioned HPC. The use of HPC in combination with 0.6-inch diameter pretensioning strands allowed the use of a single span.

Construction Method:

All precast segments were shipped 170 miles from the precast plant to the jobsite. The spread footings and other substructure components were fabricated in segments as determined by the contractor and precaster to facilitate shipping and handling, and were standardized to reduce fabrication costs. The precaster used a template in the plant fabrication to ensure adequate tolerances between the abutments, wingwalls, and footing segments. The contractor developed the assembly plan. Following placement of the footings, a minimum 3-inch thick flowable grout bed was injected through grout tubes in the footings to provide a sound bearing surface for the roughened bottom surfaces of the footings. Proper grading was assured by using leveling screws cast in the corners of each footing segment. The abutment walls and wingwalls had splice sleeve connections to accommodate the reinforcing bars protruding from the tops of the footings. The walls were lowered into place, and the splice sleeves were then grouted to complete the bar splices. All horizontal joints are full-moment connections with grouted reinforcing bars, and vertical joints have grouted shear keys. The beams were erected. A precast concrete pilaster was then set along the top of the stem wall on each side of the outside beams to provide lateral load transfer between the superstructure and substructure and to also provide a more finished look. Full-depth shear keys were then cast between each box beam, and the span was transversely post-tensioned in six locations to complete the connection between beams. A 3-bar aluminum railing was then installed. A waterproofing membrane was applied to the top surfaces of the box beams, followed by an asphalt overlay. The low traffic volume crossing the bridge in combination with a short half-mile detour allowed complete closure of the bridge during its replacement. The erection of the abutments took two days, plus a third day to cure the grout and prepare for the backfill; similar conventional cast-in-place abutments would have required 6 separate concrete placements and two months to construct. A maximum of 14 days to erect the bridge was required in the contract. The contract also included an incentive of $5,000 per day if less than 14 days, and a disincentive of the same amount if more than 14 days. The erection of the bridge, from start of footing placement to opening to traffic, required 8 days. At $5,000 per day, the contractor received a total incentive of $30,000. The bridge won two awards in the 2005 Precast/Prestressed Concrete Institute (PCI) Design Awards Program – one for “Best Bridge with Spans Between 65 and 135 ft” and the other for “Best All-Precast Solution.”

Stakeholder Feedback:

This bridge was selected for the NHDOT’s first use of totally prefabricated cantilevered substructure construction. The location minimized the overall risk of using the precast abutment system that was newly developed by a team with members from the NHDOT, FHWA, University of New Hampshire, PCI’s Northeast Region Technical Committee, and local general bridge contractors and precasters.

The NHDOT plans to use the knowledge gained from this demonstration project to design and construct future bridges with their new precast abutment system. They have developed a plan to provide standard detail sheets for prefabricated elements that can be substituted for cast-in-place concrete designs at the contractor’s option at bid, as they do precast deck panels that are partial depth. The standard sheets in the contract plans include prefabricated approach slabs, multi-column bents, and stub abutments. The contractor is required to submit an assembly plan to pull the components together if he chooses the prefabricated standards option.

The NHDOT expects this bridge to see a service life of at least 75 years due to the use of HPC, the quality of its prefabricated construction, the attention given to connection details, and an aggressive NHDOT maintenance and preservation program.

High Performance Material:

High-performance concrete (HPC) in adjacent box beams; Self-consolidating HPC in precast abutments

Project Planning

Decision Making Tools:Site Procurement:

Project Delivery: Design-bid-build

Contracting: Full lane closure; Incentive / disincentive clauses

Geotechnical Solutions

Foundations & Walls:Rapid Embankment:

Structural Solutions

Prefabricated Bridge Elements: Adjacent box beams; Precast backwalls; Precast wingwalls; Precast abutment footingsPrefabricated Bridge Systems:

Miscellaneous Prefabricated: Grouted key closure joint; Bars in splice couplers; PT ducts/bonded; Asphalt overlay w/membrane

Costs & Funding

Costs:The engineer’s estimate for the project was $0.95 million. The low bid was $1.05 million ($97,000 = 10% higher than the engineer’s estimate). There were six bidders. The cost per square foot of bridge was $218 compared to $157 for conventional construction in this region in 2004.Funding: Because this is a municipally-owned bridge, the Town of Epping contributed 20 percent of the project costs beyond the IBRC funding. Their contribution was in the form of services (pavement, machine method; pavement, hand method; uniformed officers w/ vehicle; bridge lighting system; ornamental light poles w/ luminaires; crushed gravel for drives; adjusting manhole covers and frames; adjusting/relocating hydrant; concrete filled bollard; removing small trees). The State paid for the balance of the project. In its simplest form, the funding was IBRC $690,000; State $312,000; Town $78,000.

Funding Source:

Other

Incentive Program:

IBRC (Innovative Bridge Research and Construction Program): $690,000

Additional Information

Downloadable Resources

Contract Plans:Specifications:

View 1-NH-MillSt-POW.doc

View 2-NH-Mill-SP520-Amend5-GroutBed.doc

View 3-NH-Mill-SP520-Amend422-FlowableFill.doc

View 4-NH-Mill-SP529-PCMembersWithAssembly.doc

View 1-NH-SP520-PCC.doc

View 2-NH-SP528-PSC.doc

View 3-NH-SP528-PSC-Amend.doc

Construction Schedule:

Other Related Information:

Mill-Street-PCI-Journal-May-June-2005

Summary Sheet:

111114-ABC_New_NH_2004_Mill-Street-Epping

Other Related URLs:

Go to:

http://www.fhwa.dot.gov/bridge/prefab/successstories/091104/

Go to:

http://pcine.org/cfcs/cmsIT/baseComponents/fileManagerProxy.cfc?method=GetFile&fileID=1F90ED71-A587-64FD-876BF791E98AF825

New Hampshire Department of Transportation

Contacts

David L. Scott, P.E.

In-House Design Chief, Bureau of Bridge Design

New Hampshire Department of Transportation

dscott@dot.state.nh.us

603-271-2731