State: NC

County:

Owner: State

Location: Urban

Spans: > Three-span

Beam material: Concrete

Max Span Length (ft.): 51

Total Bridge Length (ft.): 252

Construction Equipment Category: Conventional

ABC Construction Equipment: Conventional

State ID Number: B-5016

NBI Number: 950039

Coordinates

Latitude: 35.137001 | Longitude: -75.9014435

Bridge Description

Project Summary:Project Location:

North Carolina Highway 12 (NC 12) over Molasses Creek on Ocracoke Island in Hyde County

Impact Category:

Tier 5 (within 3 months)

Mobility Impact Time:

ABC: One of 7 bridges; all 7 bridges were replaced in a total of 74 days ; Conventional: 2 years

Primary Drivers:

reduced length of traffic impacts; reduced onsite construction time; improved work-zone safety; improved site constructability; improved material quality and product durability; minimized environmental impacts; reduced life-cycle cost

Dimensions:

252-ft-long and 36-ft-wide five-span adjacent prestressed cored slab beam bridge (51 ft - 50 ft - 50 ft - 50 ft - 51 ft)

Average Daily Traffic (at time of construction):

7800

Traffic Management (if constructed conventionally):

Traffic management alternative, if constructed conventionally: use of adjacent beach as a detour route

Existing Bridge Description:

The existing 20-span timber deck on timber joists was 152 ft long with a 22.5-ft-wide clear roadway. The substructure consisted of timber caps on timber piles. It had two 10-ft-wide +/- traffic lanes with two 1-ft-wide +/- shoulders. Built in 1956, the bridge was deteriorated and functionally obsolete, requiring replacement.

Replacement or New Bridge:

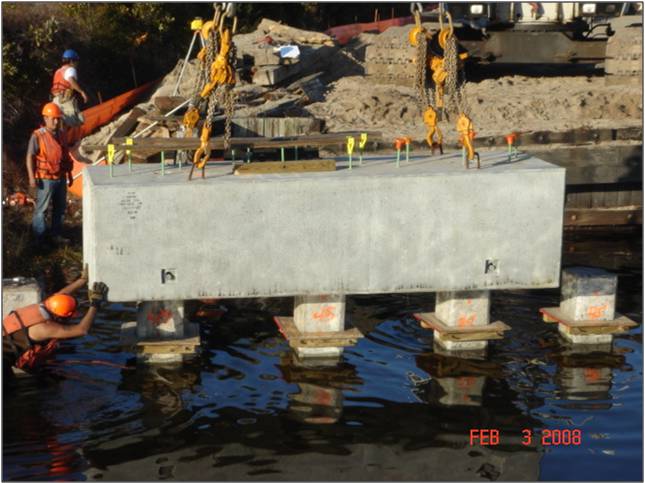

The replacement bridge has two 12-ft-wide traffic lanes with two 4.5-ft-wide shoulders. The cross-section consists of twelve 3-ft-wide by 1.75-ft-deep adjacent pretensioned cored slabs, with two 1-ft-diameter voids. The precast pile caps were founded on nine 16-square-inch prestressed concrete composite piles that were each 26.5 ft long with bolted 20-ft-long steel HP 10×57 pile extensions. The precast abutments were each founded on six 12-square-inch prestressed piles and consisted of precast caps, backwalls, wingwalls, and wing footings. Additional precast elements included parapets and end posts.

This bridge is one of seven bridges that NCDOT replaced in a project along a 2.5-mile section of NC 12 on Ocracoke Island from January to March 2008. The seven existing bridges ranged in length from 36 ft to 152 ft; the replacement bridges ranged in length from 122 ft to 252 ft. A uniform design was used across all seven bridges. The bridges were designed for seismic performance category A.

Construction Method:

The 3.67-ft-wide by 3-ft-deep by 42-ft-long precast abutment caps were fabricated in two 21-ft-long segments. Each abutment cap had partial-depth voids to facilitate pile placement, with 2-inch-diameter grout tubes extending from the top of each void to the top surface of the cap. A 1-ft-wide by 1.75-ft-tall backwall was fabricated in three 14-ft-long segments. The 4-ft-wide by 3-ft-deep by 38.42-ft-long precast pile caps were fabricated in three segments that ranged from 12 to 13 feet in length. Each bent cap segment had partial-depth voids to facilitate pile placement, with 2-inch-diameter grout tubes extending from the top of each void to the top surface of the cap. The contractor proposed and NCDOT approved a field change to precast the outside cored slab beams complete with the 17-inch-wide by 31-inch-tall concrete parapets; the parapets included anchor assemblies for metal rail attachment. The concrete mix design for all precast elements included silica fume, Class F fly ash, or calcium nitrite.

The precast elements were trucked to the bridge site. The National Park Service permitted the use of three locations for staging due to the limited private property on the island.

Prior to closing the bridge, the contractor closed one of the two traffic lanes to drive piles through the existing deck. Traffic was then detoured and the bridge was demolished. No debris was allowed to fall in the creek. The remaining piles were driven. A crane was used to erect the precast abutment caps and bent caps onto the piles with a 1-inch-wide joint between segments. The abutment wing spread footings were placed, and the wingwalls were placed on dowels located in the footings. The cap voids and dowel connections were grouted. Backfill was placed.

The adjacent cored slab beams were erected onto elastomeric bearing pads. The precast backwalls were erected over the dowels extending from the tops of the abutment caps. Transverse 0.5-inch-diameter post-tensioning strands were threaded through 2-inch-diameter holes in the beams at quarter points and stressed; the ducts were not grouted. Backwall connections to the abutment cap and shear keys between beams were filled with grout. The metal railing was attached to the precast parapets. An asphalt overlay was applied without a waterproofing membrane, and the bridge was opened to traffic.

The contract required a maximum closure of 74 days, from January 2 to March 15, 2008 to replace the seven bridges in the project, with all bridges to be opened prior to Easter. Conventional staged construction would have required two construction seasons. The contract included incentives/disincentive of $10,000 per day for exceeding the maximum road closure time, up to $100,000. The contract also included an on-time project completion incentive for completion on or before March 15 of $250,000. The contract included a mandatory pre-bid meeting.

The bridges were opened to traffic on March 5, ten days early. The contractor received the total incentive and bonus of $350,000.

Stakeholder Feedback:

Involve the public early in the planning process.

High Performance Material:

The concrete mix design for all precast elements included silica fume, Class F fly ash, or calcium nitrite.

Project Planning

Decision Making Tools:Site Procurement:

Project Delivery: Design-bid-build

Contracting: Full lane closure; Incentive / disincentive clauses; Lump sum bonus; Contractor revision

Geotechnical Solutions

Foundations & Walls:Rapid Embankment:

Structural Solutions

Prefabricated Bridge Elements: Adjacent slab beams; Precast pile caps; Precast abutment caps; Precast backwalls; Precast wingwalls; Precast abutment footingPrefabricated Bridge Systems:

Miscellaneous Prefabricated: Grouted key closure joint; PT ducts/un-bonded; Socket connection (in precast caps); Grouted duct connection (in precast backwalls); Asphalt overlay w/o membrane; Prefabricated railing

Costs & Funding

Costs:The engineer’s estimate for the project was $6.70 million. The low bid was $8.02 million. There were three bidders. The cost per square foot of bridge was $250 compared to $120 for conventional construction in this region in 2008. The increased cost was due to the extreme location of the bridges, the tight time restrictions, and the increased storm risk.

Cost estimate comparison for 2-year conventional construction:

(1) Estimated 4 bridges staged construction, one year contract time – approx. $3.8M;

(2) Estimated 3 bridges staged construction, one year contract time – approx. $2.5M;

(3) NCDOT planning, design, and inspection – approx. $2M;

(4) Inflation = approx. $700,000;

(5) Total staged cost estimate = approx. $9M;

(6) Approximate cost of fast track = approx. $600,000.

Funding Source:

Incentive Program:

Additional Information

Downloadable Resources

Contract Plans: View 121219-ABC_New2_NC_2008_NC12-over-MolassesCreek.pdf

View Hyde-39-Specifications-Schedule.pdf

Construction Schedule:

Other Related Information:

Ocracoke-Bridge-Presentation-1.5

Summary Sheet:

121219-ABC_New2_NC_2008_NC12-over-MolassesCreek

Other Related URLs:

North Carolina Department of Transportation

Contacts

Brian C. Hanks,

P.E.

Project Engineer

North Carolina Department of Transportation

bhanks@ncdot.gov

919-707-6419