Group: Decks

Subject: FRP Decks

State: Missouri Abstract:

Although still in their infancy, fiber-reinforced polymer (FRP) bridges have shown great promise in eliminating corrosion concerns and meeting (or exceeding) FHWA’s goal of 100-year life spans for bridges. While FRP bridges are cost-effective in terms of life cycle analyses, the combination of higher first costs and limited state DOT budgets has restricted their use. One area that has shown some headway is the use of FRP for bridge decks, focusing on the location where the majority of corrosion-related damage normally occurs. However, first costs still hamper widespread use of this approach.

FRP bridge deck panels offer superior corrosion resistance, at one-fifth the weight of reinforced concrete. However, current FRP bridge deck panels typically rely on an intricate geometric honeycomb system between the top and bottom layers of the sandwich panel. This labor-intensive honeycomb construction more than doubles the cost of FRP panels compared to reinforced concrete. Although cost-effective in terms of longevity of the bridge and overall reductions in weight, the lower first cost of reinforced concrete precludes the use of FRP bridge decks in the majority of situations.

Closed-cell, high-density polyurethane foams lower first cost, offering a cost-effective alternative to the complex honeycomb construction. Structural sandwich panels with a polyurethane foam infill are well established in other commercial applications, such as automobiles, aircraft, and prefabricated buildings. Several recent advances in polyurethane foam formulations have resulted in a material that can resist the localized compressive stresses and fatigue loading beneath a truck wheel, making this type of sandwich panel construction a viable alternative for bridge decks. Once these panels can compete against reinforced concrete on a first-cost basis, their significantly longer life expectancies will save considerable money for MoDOT and the residents of Missouri.

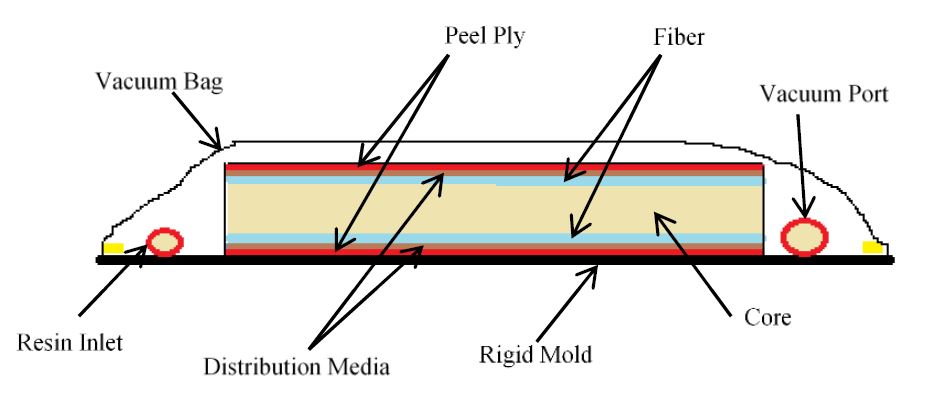

The objective of the research was to develop, test, and evaluate fiber-reinforced, polyurethane (PU) foams to replace the costly honeycomb construction currently used to manufacture FRP bridge deck panels. Initially, the effort focused on developing an FRP sandwich panel to replace the precast, stay-in-place forms currently used to construct reinforced concrete bridge decks. However, during the course of the project, the research effort expanded to include full-depth bridge deck panels as well. This report documents the results of this study.

Key Words: Bridge Decks, Composites, Corrosion, Durability, Fiber-Reinforced Polymers, Polyurethane Foam, Vacuum-Assisted Resin Transfer Molding.

Specific ABC aspect:

Budget and Timeline

Budget (USD):

Project length:

Project Starting Year: 2014

Project Completion Year: 2014

Primary Sponsor

Missouri Department of Transportation Construction and Materials

P. O. Box 270

Jefferson City, MO 65102 USA

Primary Performing Organization

Missouri University of Science and Technology

331 Butler Carlton Hall

1401 North Pine Street

Rolla, MO 65409 USA

PI: Jeffery Volz SE, PE, PhD

volz@ou.edu

Other Documents

View Polyurethane-Foam-Infill-for-Fiber-Reinforced-Polymer-FRP-Bridge-Deck-Panels-report.pdf

Other Related URLs

Go to: https://library.modot.mo.gov/RDT/reports/TRyy1203/cmr14-016.pdf

Go to: http://www.trb.org/Main/Blurbs/170946.aspx